By Maureen Storey

This article was published in the April 2024 edition of Soul Search, the Journal of The Sole Society

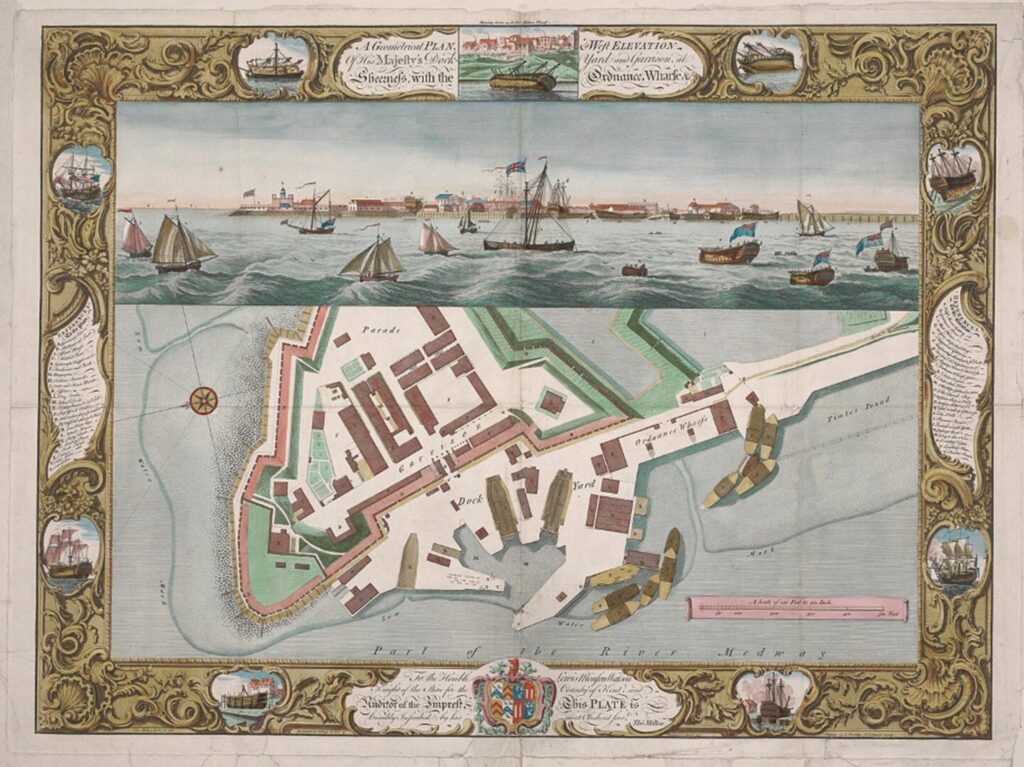

Although nowadays considered a quiet backwater, the Isle of Sheppey features strongly in the Society’s eighteenth and nineteenth century records for north Kent. The reason for this is the Royal Naval dockyard, constructed on the marshy land of the Sheerness peninsular, which gave employment to thousands of men, many of whom were highly skilled.

Historically RN dockyards were sited close to safe anchorages, where ships could be repaired and re-provisioned. In the early seventeenth century the Navy’s three dockyards in southeast England were at Chatham on the banks of the River Medway and at Deptford and Greenwich, both on the River Thames. Although these did, indeed, have safe anchorages, they all shared the disadvantage that depending on the wind and tide it could be difficult and time consuming to work a sailing ship up and down river. It wasn’t unknown for it to take days rather than hours for a large vessel to move between Chatham and the open sea. The problem was partially solved by anchoring ships that needed only minor repairs and re-provisioning in an area of sea sheltered by the Nore, a sandbank just off the Isle of Sheppey. These ships didn’t have to enter the river and could be returned to service more quickly. However, as there were no settlements close to the anchorage, it meant that the materials required for the repairs, the fresh provisions and any additional workmen had to be ferried up the river from Chatham or Queenborough, another time-consuming factor.

It was the declaration of war with the Netherlands in March 1665 that prompted the Admiralty to remedy the problem. In this war, geography dictated that it was the south-eastern dockyards that would be most involved with repair and resupply, so to alleviate the bottlenecks caused by the dockyards’ locations, a compound with a wooden storehouse were built on Sheerness point, the closest land to the Nore anchorage. As more ships were anchored at the Nore for repair shipwrights were hastily moved from Deptford and Greenwich and an ad hoc collection of sheds and jetties were built near the compound. By July a plan for a proper dockyard for Sheerness had been approved and by November the new dockyard was fully operational. Work on fortifying the site began in April 1667, but halted when it was attacked and captured by the Dutch fleet, which then used it as a base for a raid on the English ships anchored in the Medway.

After the raid, work began on considerably more robust fortifications and then on the dockyard itself. The greatly enlarged fort left only a comparatively small area for the dockyard, which caused operational and developmental difficulties. To aid the construction several hulks were positioned on the foreshore to act as breakwaters, but soon these were also being used to house workers and as workshops. The space between the hulks was filled with soil and new hulks added on the created land. Dockyard construction was hampered by a lack of workers due to the scarcity of available housing, the lack of fresh water, and ague, a form of malaria, arising from the surrounding marshes. Nevertheless by 1672 the dockyard was largely complete and officers were appointed to its key positions: John Shish as Master Shipwright, Samuel Hunter as Clerk of the Cheque and John Daniell as Storekeeper. At this point the dockyard did not have a dry dock – the first was added in 1708 and a second in 1720.

Because there was no established settlement nearby, the accommodation for Sheerness workers was initially provided by the Navy Board, first in the hulks and as these began to decay in brick-built barracks within the docks. The last four hulks were still being used for housing in 1801, and, despite their decayed condition, they were only demolished then because the land on which they stood was needed for development. In total, 186 families, including some Soles, were rehoused as a result. By 1774 the Navy Board was providing accommodation for nearly 1000 workers and their families. In addition, in the 1730s the first civilian settlements had begun to grow outside the dockyard. The first of these houses were built by the workers themselves just outside the ramparts, using scrap materials taken from the dockyard. They were clinker-built like ships and the outsides were painted naval grey-blue (this being the only paint available in the dockyard). The area was initially called ‘Blue Houses’ but over time this became ‘Blue Town,’ the name by which the area is still known. Later in the eighteenth century, another settlement grew up about a mile from the dockyard (predictably known as Mile Town) and from this grew the modern town of Sheerness.

By the early nineteenth century the area of the dockyard that had grown up over the buried hulks was becoming unstable and in 1815 the rebuilding of a much-enlarged dockyard began. Despite the engineering difficulties arising from building on mud banks and quicksand, the new dockyard was completed by 1830. New garrison buildings were then erected to the north of the new dockyard and more fortifications were built along the foreshore.

In 1830s the Royal Navy was beginning to consider using steam propulsion for warships and Sheerness started adapting to the new technology needed to repair and maintain the new steamships anchored at the Nore. This became an immediate priority at the start of The Crimean War in 1854, with a new steam factory being hastily built and a mast house converted to an engineering foundry and fitting shop. By 1868, this area of the dockyard employed about 500 men and boys.

Although in its early days a few ships had been built at the dockyard, it had always been intended that Sheerness would be used primarily for repair and refitting, and it was announced in 1824 that this was to continue to be its primary function. However, by the middle of the nineteenth century Sheerness’s dry docks were increasingly used for shipbuilding. By 1904 over 100 ships had been built there, including HMS Salamander in (1832) (one of the Royal Navy’s first paddle steamers), HMS Rattler (1843) (the first warship to use screw propulsion), HMS Diamond (1874) (the last all-wooden ship to be built in the dockyard) and HMS Cadmus (1904), the last ship built in the dockyard. Of the Sheerness-built ships, only HMS Gannet (1878), a screw sloop-of-war, still survives – she is part of the National Historic Fleet and is now preserved at Chatham Dockyard.

In the early twentieth century, the Admiralty decided to stop shipbuilding at Sheerness in order that the dockyard could take on a new specialist role: that of refitting torpedo boats and torpedo boat destroyers. Although this kept the dockyard fully employed until the end of World War I, work was much scarcer during the interwar years, with most of the time spent putting the final touches to ships built elsewhere. During World War II a flotilla of mine sweepers was stationed at Sheerness and, although a number of motor launches were built there, its main function was again the repair and refitting of war-damaged vessels. Post World War II work for the dockyard again declined and in 1958 its closure was announced. The shipyard was decommissioned on 31 March 1960, when all of its 2500 workers were made redundant. The dockyard was taken over by the Medway Port Authority, a private company, and turned into a commercial port.

Over the years RN dockyards have offered a wide range of employment to skilled craftsmen including shipwrights, house carpenters, cabinetmakers, caulkers, ropemakers, mastmakers, joiners, sailmakers, riggers, blacksmiths, painters, all of whom had to serve a seven-year apprenticeship. In the seventeenth century apprenticeships started at the age of 16, though this was later lowered to 14. The UK’s Register of Duties Paid for Apprentices’ Indentures (1710-1811) lists some of the apprentices and masters at Sheerness in that period:

1713: John Sole, master, carpenter, Ise of Sheppey: Henry Broadsheet, apprentice

1736: John Sole, master, carpenter, Eastchurch: Thomas Chapman, apprentice

1768: Daniell Tassell, master, house carpenter, Sheerness: John Sole, apprentice

1770: John Sole, master, carpenter, Sheerness: William Atkinson, apprentices

1773: John Morse, carpenter, Sheerness: Thomas Sole, apprentice

1775: James Clark, sailmaker, Sheerness. William Soles, apprentice

1792: John King, carpenter, Sheerness Dockyard: John Sole, apprentice

Of the classes of work that involved carpentry skills, shipwrights were the most highly paid, then cabinetmakers and then the house carpenters (In this context a house carpenter is someone who works on buildings of all sorts, not just houses.) At the end of his apprenticeship, a shipwright was known as a working shipwright. If he was thought to show promise he would eventually be promoted to a quarterman of shipwrights and then to a leading man of shipwrights. Both promotions involved supervision of a group of shipwrights. These three positions were all paid by the hour, so the men received no money if they were off sick or injured – in effect a zero hours contract. For successful leading men the next step up the ladder was to become an inspector of shipwrights, which was the lowest of the salaried positions and therefore offered more security. Further promotion led to becoming first a foreman of the yard, then a senior foreman of the yard, then assistant master of the yard, then Master Shipwright of the Yard and finally to Surveyor of the Navy. The three most senior positions involved warship design, dockyard management and timber selection,

Similar hierarchies existed for the other dockyard trades. For example, Thomas Sole served as the Master Joiner from 1811 until the post was abolished in 1822. His career progression reads:

8 Oct 1773: appointed Servant at Sheerness dockyard (his first salaried position?)

8 Oct 1780: appointed Joiner at Sheerness

25 Jul 1806: appointed Foreman of the Ships Afloat

16 Nov 1811: appointer Master Joiner at Sheerness dockyard

Because RN dockyards were run as quasi-military organisations, meticulous records were kept and it is often possible to follow a particular man’s career through the dockyard paybooks, musters, etc. which are kept in the National Archives at Kew. Unfortunately, these have yet to be indexed, so research can only be conducted at Kew and is very time consuming. Hopefully, the records will eventually be indexed and possibly digitised, but until then most of what we know about the Sheerness dockyard workforce comes from the usual family history sources: church registers, censuses, and wills.

From these it is apparent that men moved between RN Dockyards. For example, John Sole, who was baptised in 1754 in Minster, Isle of Sheppey and married there in 1777, was living in Sheerness when his three children were born, but in his will of 1829, he is described as ‘of Deptford, late master house carpenter of His Majesty’s Dockyard Deptford.’ Similarly, William Sole, son of William Sole, a sailmaker of Sheerness, moved to Portsea in Hampshire, home of many of the Portsmouth dockyard workers and is described in his will of 1840 as a superannuated joiner, which almost certainly means he was receiving a dockyard pension.

The workers of in Sheerness Dockyard that we currently know of are almost exclusively Soles but while researching this article I came across the will of Thomas Wilson Sewell, shipwright of Sheerness, who died in 1782. Thomas was born in Thanet, Kent, in 1757, and was the son of John and Ann Sewell. He married Rebecca Simmons in Minster, Isle of Sheppey, in 1779, but as no children are mentioned in the will he seems to have died childless. Most of his estate was left to his brother John. If anyone can fit him into a wider Sewell family perhaps they could let our Sewell coordinator, Tony Storey, know.

Although over the years we have built up sizeable family trees for most of the dockyard families, we haven’t been able to take any of them back to before the founding of the dockyard. There do not seem to be any Sole families on the Isle of Sheppey before that, so presumably the dockyard was the attraction that drew them there. Shipbuilding was an important industry in many Kentish ports, so perhaps they didn’t move far, but it is also possible that at least some moved from the older Admiralty dockyards in the Thames or from Portsmouth and Southampton.